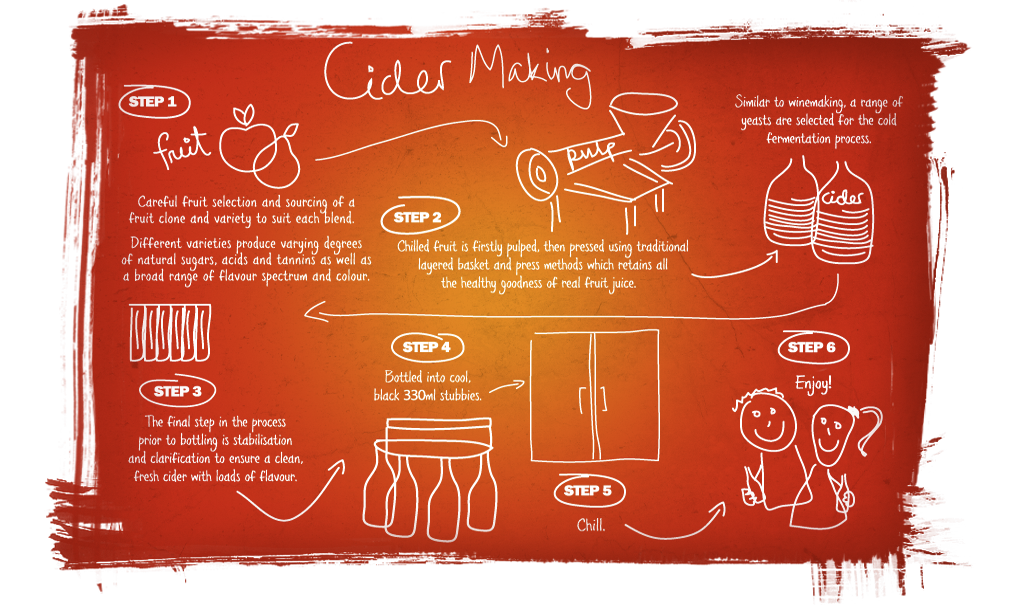

Making the Cider

Our Cider Maker

Nyall Condon

A highly accomplished winemaker by trade, Nyall branched out into cider making in 2010 with the birth of Flying Brick. He is the master craftsman behind your favourite ‘Bricks’ (and has a passion for exploring palate boundaries when crafting up specialty, boutique batches in the onsite cidery). Nyall is a founding Executive Committee member of Cider Australia as well as being a highly regarded Cider Judge.

Step 1

Careful fruit selection and sourcing of a fruit clone and variety to suit each blend. Different varieties produce varying degrees of natural sugars, acids and tannins as well as a broad range of flavour spectrum and colour.

Step 2

Chilled Fruit is firstly pulped then pressed using traditional layered basket and press methods which retains all the healthy goodness of real fruit juice. Similar to wine making a range of yeasts are selected for the cold fermentation process.

Step 3

The final step in the process prior to bottling is stabilisation and clarification to ensure a clean, fresh cider with loads of flavour.

Step 4

Bottled into cool, black 330ml stubbies.

Step 5

Chill

Want Cider and want it now? Order today and we'll ship your order for free - anywhere in Australia!

Visit our Cider Shop Now